The Definitive Guide to Torquing Lug Nuts: Safety and Precision for Wheel Security

Lug nuts. They might seem like the simplest part of your vehicle, but these small fasteners are responsible for holding your wheels securely to the hubs. Improperly torqued lug nuts can lead to serious consequences, from annoying vibrations to catastrophic wheel detachment. This guide will walk you through the proper techniques for torquing lug nuts, ensuring safety, performance, and peace of mind.

Why Torquing Lug Nuts Correctly Matters

The importance of properly torquing lug nuts cannot be overstated. Here’s a breakdown of why it’s essential:

- Safety: The most crucial reason. Under-torqued lug nuts can loosen over time, potentially causing the wheel to wobble and eventually detach while driving. Over-torqued lug nuts can stretch or break the studs, also leading to wheel failure.

- Wheel Damage: Unevenly torqued lug nuts can warp the wheel hub or rotor, leading to vibrations, premature wear, and potentially costly repairs.

- Brake Performance: Distorted rotors due to improper lug nut torque can negatively impact braking performance, increasing stopping distances and reducing control.

- Tire Wear: A wobbly or misaligned wheel due to loose lug nuts can cause uneven tire wear, shortening the lifespan of your tires.

- Component Life: Over-torqued lug nuts can stress the wheel studs and bearings, leading to premature failure of these components.

Understanding Torque

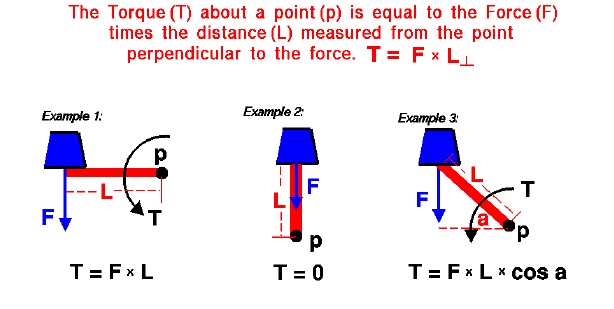

Torque is a twisting force that measures how tightly a fastener is tightened. It is typically measured in foot-pounds (ft-lbs) or Newton-meters (Nm). The specified torque value for your vehicle’s lug nuts represents the optimal amount of force required to securely clamp the wheel to the hub without over-stressing the components.

Finding the Correct Torque Specification

The first step in properly torquing lug nuts is to find the correct torque specification for your vehicle. Here’s where to look:

- Owner’s Manual: This is the most reliable source. The torque specification will typically be listed in the section on wheel maintenance or tire changes.

- Door Jamb Sticker: Some vehicles have a sticker on the driver’s side door jamb that includes tire and wheel information, including the lug nut torque specification.

- Online Resources: Reputable automotive websites and forums often have databases of torque specifications for various vehicles. However, double-check the information against another source.

- Tire Shop: If you’re unsure, a professional tire shop can quickly provide the correct torque specification for your vehicle.

Tools You’ll Need

- Torque Wrench: This is the most important tool. A torque wrench is specifically designed to apply a precise amount of torque. Use a calibrated torque wrench to ensure accuracy. There are two main types:

- Click-Type: You set the desired torque, and the wrench clicks when that torque is reached.

- Digital: Provides a digital readout of the torque being applied, often with an audible alert when the target torque is reached.

- Socket: Use the correct size socket for your lug nuts. Using the wrong size can damage the lug nuts or the socket. Typically, you’ll need a deep socket to accommodate the length of the wheel studs.

- Lug Wrench (Optional): A standard lug wrench can be used to initially loosen or tighten the lug nuts before using the torque wrench.

- Gloves: To protect your hands.

- Wheel Chocks: To prevent the vehicle from rolling.

- Wire Brush: To clean any debris from the threads of the wheel studs.

The Torquing Process: Step-by-Step

Follow these steps to ensure your lug nuts are torqued correctly:

-

Preparation:

- Park the vehicle on a level surface.

- Engage the parking brake firmly.

- Place wheel chocks behind the wheels that will remain on the ground.

- Gather your tools and the correct torque specification.

-

Loosening the Lug Nuts:

- If you are removing a wheel, use a lug wrench to loosen the lug nuts slightly. Don’t remove them completely at this stage. Loosen them in a star pattern (see step 5).

- If you’ve just had your tires changed, you may want to loosen the lug nuts and re-torque them yourself to ensure they’re done correctly.

-

Installing the Wheel:

- Carefully mount the wheel onto the hub, aligning the wheel studs with the holes in the wheel.

- Hand-tighten the lug nuts evenly until they are snug against the wheel.

-

Initial Tightening:

- Use the lug wrench to tighten the lug nuts a bit more, but don’t fully tighten them yet. Tighten them in a star pattern (see step 5).

-

The Star Pattern (Critical):

- The star pattern (also known as a criss-cross pattern) is crucial for even distribution of torque and clamping force.

- Imagine the lug nuts as points on a star. Tighten one lug nut, then skip to the lug nut directly opposite it. Continue this pattern until all lug nuts are snug.

-

Torquing with the Torque Wrench:

- Set the torque wrench to the specified torque value.

- Attach the correct size socket to the torque wrench.

- Place the socket onto a lug nut and slowly and smoothly apply pressure to the torque wrench until it clicks (if using a click-type wrench) or reaches the target value (if using a digital wrench).

- Repeat this process for each lug nut, following the star pattern.

- It’s best to torque the lug nuts in multiple passes. For example, if the specified torque is 100 ft-lbs, you could first torque them to 60 ft-lbs in the star pattern, then to the full 100 ft-lbs in the star pattern.

-

Double-Check:

- After torquing all the lug nuts, go around the wheel one more time to double-check that each lug nut is properly torqued.

-

Lowering the Vehicle:

- Carefully lower the vehicle to the ground.

-

Final Torque Check:

- Once the vehicle is on the ground, perform a final torque check on all lug nuts, again following the star pattern.

Important Considerations and Tips

- Never Use an Impact Wrench to Torque: Impact wrenches are powerful tools that can easily over-torque lug nuts, leading to damage. Always use a torque wrench for the final tightening.

- Clean the Threads: Before installing the wheel, use a wire brush to clean any rust, dirt, or debris from the wheel studs. Clean threads ensure accurate torque readings.

- Lubrication: Unless specifically recommended by the vehicle manufacturer, do not apply lubricant (such as oil or grease) to the wheel studs or lug nuts. Lubrication can affect the torque reading and potentially lead to over-tightening.

- Re-Torque After Driving: It’s recommended to re-torque the lug nuts after driving approximately 50-100 miles after a wheel change. This helps to ensure that they remain properly tightened as the wheel settles onto the hub.

- Torque Wrench Calibration: A torque wrench should be calibrated periodically to ensure accuracy. Check the manufacturer’s recommendations for calibration intervals.

- Damaged Studs or Lug Nuts: If you notice any damage to the wheel studs or lug nuts (e.g., stripped threads, cracks), replace them immediately.

- Professional Installation: If you’re not comfortable performing this task yourself, have a professional tire shop change your tires and torque the lug nuts to the correct specification.

Consequences of Improper Torquing

- Under-Torqued: Lug nuts can loosen over time, leading to wheel wobble, vibration, and potential wheel detachment.

- Over-Torqued: Lug nuts can stretch or break the wheel studs, warp the wheel hub or rotor, and make it difficult to remove the wheel in the future.

Conclusion

Torquing lug nuts correctly is a fundamental aspect of vehicle maintenance that directly impacts safety and performance. By following the steps outlined in this guide, using the right tools, and paying attention to detail, you can ensure that your wheels are securely fastened and enjoy a safe and reliable driving experience. Remember to always prioritize safety and consult your vehicle’s owner’s manual for specific torque specifications. If you’re ever in doubt, seek the assistance of a qualified automotive professional.