How to Rebuild a Carburetor on a Classic Car

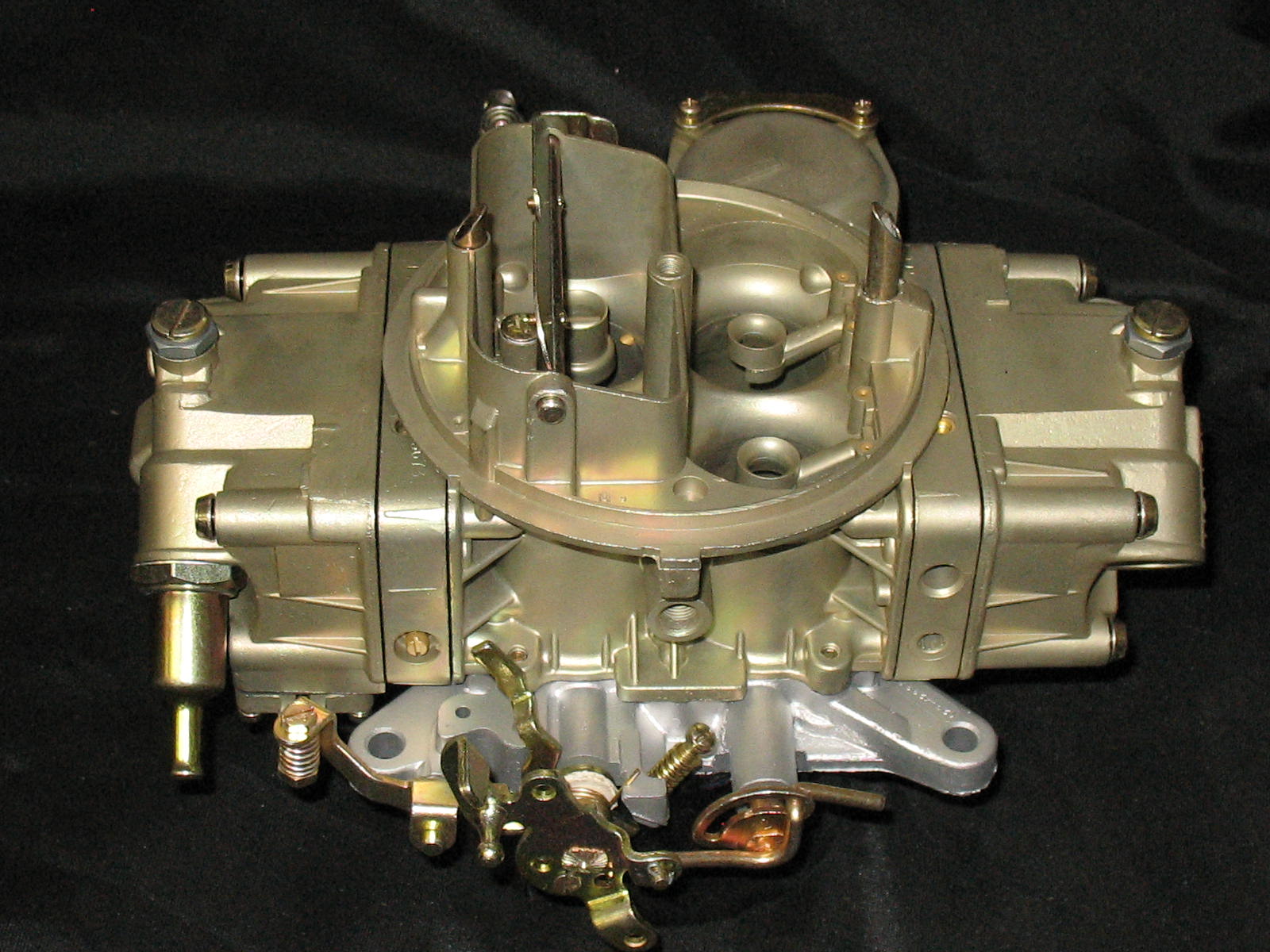

For classic car enthusiasts, the allure of vintage vehicles extends beyond their timeless aesthetics. It’s the connection to a bygone era of automotive engineering, where mechanical ingenuity reigned supreme. At the heart of many classic cars lies the carburetor, a marvel of simple yet effective technology responsible for mixing air and fuel to create the combustion needed to power the engine.

However, carburetors are susceptible to wear and tear over time. Deposits can accumulate, gaskets can dry out, and components can corrode, leading to poor engine performance, reduced fuel economy, and starting difficulties. When these issues arise, rebuilding the carburetor becomes a necessary task to restore your classic car’s performance and reliability.

Understanding the Carburetor

Before diving into the rebuilding process, it’s crucial to understand the basic principles of how a carburetor works. In essence, the carburetor uses the vacuum created by the engine’s intake stroke to draw fuel from the fuel bowl and mix it with air. This air-fuel mixture is then delivered to the engine’s cylinders for combustion.

The carburetor consists of several key components:

- Float Bowl: This reservoir holds a constant supply of fuel at the correct level.

- Float: A buoyant device that regulates the fuel level in the float bowl.

- Needle Valve: Controls the flow of fuel into the float bowl, maintaining the proper fuel level.

- Main Jets: Meter the amount of fuel delivered to the engine at higher speeds.

- Idle Jets: Control the fuel flow when the engine is idling.

- Venturi: A constricted passage that increases air velocity, creating a vacuum to draw fuel into the airstream.

- Throttle Plate: Controls the amount of air entering the engine, regulating engine speed.

- Choke: Restricts airflow into the carburetor, creating a richer fuel mixture for cold starting.

When to Rebuild Your Carburetor

Several telltale signs indicate that your carburetor needs rebuilding:

- Poor Engine Performance: Hesitation, stumbling, or lack of power during acceleration.

- Reduced Fuel Economy: A noticeable decrease in miles per gallon.

- Rough Idling: Unstable or erratic engine idling.

- Black Smoke from Exhaust: Indicates a rich fuel mixture.

- Fuel Leaks: Fuel dripping from the carburetor body.

- Difficulty Starting: Especially in cold weather.

Tools and Materials Needed

Rebuilding a carburetor requires a few specialized tools and materials:

- Carburetor Rebuild Kit: Contains gaskets, seals, O-rings, and replacement parts specific to your carburetor model.

- Carburetor Cleaner: A solvent designed to dissolve deposits and varnish.

- Parts Tray: To organize and keep track of small components.

- Screwdrivers: Various sizes, including flathead and Phillips head.

- Wrenches: Metric or SAE, depending on your car’s make and model.

- Pliers: For removing and installing small parts.

- Compressed Air: To blow out passages and clean components.

- Soft Brush: For gentle scrubbing.

- Eye Protection: Safety glasses to protect your eyes from debris and chemicals.

- Gloves: To protect your hands from solvents and grime.

- Shop Manual: A detailed guide specific to your carburetor model is invaluable.

- Digital Camera: To document the disassembly process for reference.

The Rebuilding Process

-

Preparation:

- Park your classic car in a well-ventilated area and disconnect the negative battery cable.

- Gather your tools, materials, and the carburetor rebuild kit.

- Consult your shop manual for specific instructions and diagrams for your carburetor model.

- Take pictures of the carburetor from different angles before disassembly to aid in reassembly.

-

Removal:

- Carefully disconnect the fuel lines, vacuum lines, and electrical connections from the carburetor.

- Remove the linkage connecting the carburetor to the throttle and choke.

- Loosen the carburetor mounting bolts and carefully remove the carburetor from the intake manifold.

- Place a clean rag over the intake manifold opening to prevent debris from entering the engine.

-

Disassembly:

- Place the carburetor on a clean workbench and begin the disassembly process.

- Carefully remove each component, referring to your shop manual and the pictures you took.

- Pay close attention to the order of disassembly and the location of each part.

- Place the components in a parts tray, organizing them by section or function.

- Be gentle when removing jets and other small parts to avoid damaging them.

-

Cleaning:

- Once the carburetor is completely disassembled, thoroughly clean all the components.

- Use carburetor cleaner to soak the metal parts, removing deposits, varnish, and grime.

- Use a soft brush to scrub away stubborn residue.

- Rinse the parts with clean water and dry them with compressed air.

- Pay special attention to cleaning the jets and passages, ensuring they are free of obstructions.

- Inspect the carburetor body for cracks, damage, or stripped threads.

-

Inspection and Replacement:

- Carefully inspect all the components for wear, damage, or corrosion.

- Replace any parts that are worn, damaged, or questionable with new components from the rebuild kit.

- Pay close attention to the condition of the gaskets, seals, and O-rings, replacing them with new ones.

- Check the float for leaks or damage, and replace it if necessary.

- Inspect the needle valve and seat for wear, and replace them as needed.

-

Reassembly:

- Begin reassembling the carburetor, following the reverse order of disassembly.

- Refer to your shop manual and the pictures you took to ensure correct placement of each component.

- Use new gaskets, seals, and O-rings from the rebuild kit.

- Tighten all screws and bolts to the specified torque values.

- Double-check your work to ensure that all components are properly installed.

-

Adjustment:

- Once the carburetor is reassembled, make any necessary adjustments according to your shop manual.

- Adjust the float level to the specified height.

- Adjust the idle mixture screws to achieve a smooth idle.

- Adjust the choke to ensure proper cold starting.

-

Installation:

- Carefully install the rebuilt carburetor onto the intake manifold, using a new carburetor base gasket.

- Tighten the mounting bolts to the specified torque values.

- Reconnect the fuel lines, vacuum lines, and electrical connections.

- Reconnect the linkage to the throttle and choke.

-

Testing and Tuning:

- Reconnect the negative battery cable and start the engine.

- Allow the engine to warm up to operating temperature.

- Check for fuel leaks and address any issues immediately.

- Fine-tune the carburetor adjustments to achieve optimal engine performance.

- Adjust the idle speed and mixture screws until the engine idles smoothly and responds well to throttle input.

- Take the car for a test drive and monitor its performance.

Tips for Success

- Work in a Clean and Organized Environment: A clean workspace will help you keep track of small parts and prevent contamination.

- Take Your Time: Rebuilding a carburetor is a delicate process that requires patience and attention to detail.

- Follow the Shop Manual: Your shop manual is your best resource for specific instructions and diagrams for your carburetor model.

- Don’t Be Afraid to Ask for Help: If you’re unsure about any aspect of the rebuilding process, seek guidance from experienced mechanics or online forums.

Rebuilding a carburetor on a classic car can be a rewarding experience, allowing you to restore your vehicle’s performance and reliability while gaining a deeper understanding of its mechanical workings. By following these steps and taking your time, you can successfully rebuild your carburetor and enjoy the smooth, powerful performance of your classic car for years to come.