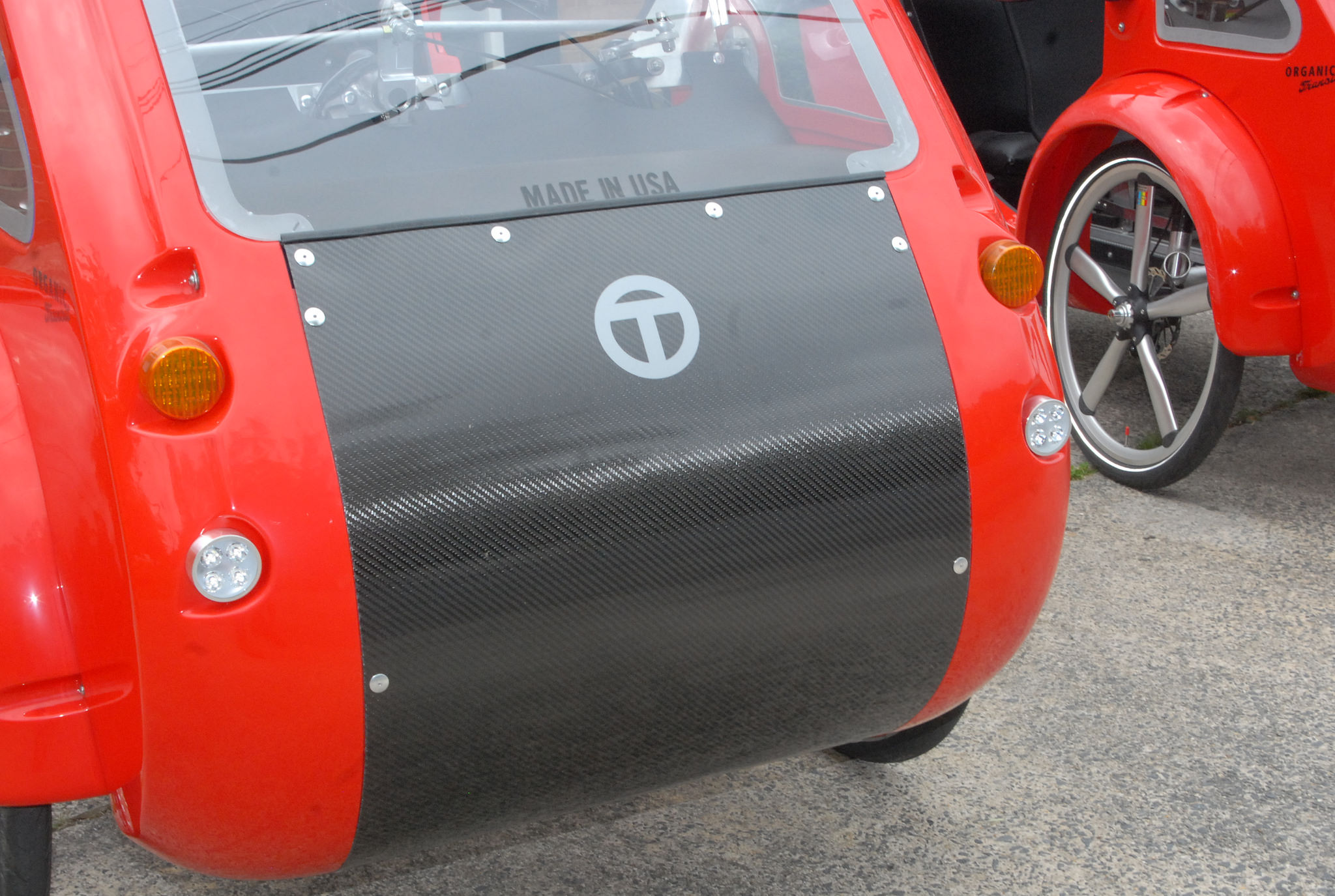

How to Repair Carbon Fiber Panels

Carbon fiber panels are known for their high strength-to-weight ratio, making them a popular choice in various industries, including aerospace, automotive, and sports equipment. However, despite their durability, carbon fiber panels are susceptible to damage from impacts, scratches, and environmental factors. Repairing carbon fiber panels requires specialized knowledge, skills, and materials. This article provides a comprehensive guide on how to repair carbon fiber panels effectively.

Understanding Carbon Fiber Panels

Before delving into the repair process, it’s essential to understand the composition and properties of carbon fiber panels. Carbon fiber panels consist of carbon fibers embedded in a resin matrix, typically epoxy. The carbon fibers provide strength and stiffness, while the resin matrix binds the fibers together and distributes loads.

Carbon fiber panels exhibit excellent mechanical properties, including high tensile strength, stiffness, and fatigue resistance. However, they are brittle and prone to cracking or delamination when subjected to excessive stress or impact. Additionally, carbon fiber panels are susceptible to degradation from UV exposure, moisture, and chemicals.

Assessing the Damage

The first step in repairing a carbon fiber panel is to assess the extent and nature of the damage. Thoroughly inspect the panel for cracks, delamination, scratches, and other defects. Use a magnifying glass or inspection camera to examine the damage closely.

Determine the size, depth, and location of the damage. Small scratches or surface imperfections may only require cosmetic repairs, while more severe damage, such as cracks or delamination, may necessitate structural repairs.

Safety Precautions

Before commencing any repair work on carbon fiber panels, it’s crucial to take necessary safety precautions to protect yourself from potential hazards. Carbon fiber dust and debris can be irritating to the skin, eyes, and respiratory system.

Wear appropriate personal protective equipment (PPE), including:

- Respirator or dust mask: To prevent inhalation of carbon fiber dust.

- Safety glasses or goggles: To protect your eyes from debris.

- Gloves: To prevent skin contact with epoxy resins and carbon fiber materials.

- Protective clothing: To cover your skin and prevent irritation.

Work in a well-ventilated area to minimize exposure to dust and fumes. Use a vacuum cleaner with a HEPA filter to collect dust and debris. Dispose of waste materials properly in accordance with local regulations.

Repair Techniques

There are several techniques for repairing carbon fiber panels, depending on the type and extent of the damage. Common repair methods include:

- Cosmetic Repair: For minor scratches, surface imperfections, or cosmetic blemishes.

- Structural Repair: For cracks, delamination, or other structural damage that compromises the panel’s integrity.

Cosmetic Repair

Cosmetic repair is suitable for addressing minor surface imperfections or scratches on carbon fiber panels. The goal is to restore the panel’s appearance without compromising its structural integrity.

Materials Required:

- Sandpaper (various grits)

- Epoxy resin

- Micro-balloons or fillers

- Clear coat or paint

- Polishing compound

- Clean cloths

- Mixing cups and sticks

Procedure:

- Prepare the Surface: Clean the damaged area with a mild detergent and water. Remove any loose debris or contaminants.

- Sand the Area: Use fine-grit sandpaper to gently sand the damaged area, feathering the edges of the scratch or imperfection.

- Mix Epoxy Resin: Mix epoxy resin according to the manufacturer’s instructions. Add micro-balloons or fillers to the resin to create a paste-like consistency.

- Apply Epoxy Mixture: Apply the epoxy mixture to the sanded area, filling in the scratch or imperfection. Use a spreader or squeegee to smooth the surface.

- Cure the Epoxy: Allow the epoxy to cure completely according to the manufacturer’s instructions.

- Sand the Repair: Once the epoxy is cured, sand the repaired area with progressively finer grits of sandpaper to blend it seamlessly with the surrounding surface.

- Apply Clear Coat or Paint: Apply a clear coat or paint to the repaired area to match the panel’s original finish.

- Polish the Surface: After the clear coat or paint has dried, polish the surface with a polishing compound to restore its gloss and luster.

Structural Repair

Structural repair is necessary for addressing cracks, delamination, or other structural damage that compromises the panel’s integrity. The goal is to restore the panel’s strength and stiffness while maintaining its original shape and dimensions.

Materials Required:

- Carbon fiber fabric

- Epoxy resin

- Vacuum bagging materials (optional)

- Heat gun or oven (optional)

- Cutting tools (scissors, knife)

- Mixing cups and sticks

- Release film

- Peel ply

- Breather fabric

Procedure:

- Prepare the Surface: Clean the damaged area with a mild detergent and water. Remove any loose debris or contaminants.

- Remove Damaged Material: Use a rotary tool or sandpaper to carefully remove the damaged carbon fiber material, creating a clean and stable surface for the repair.

- Prepare Carbon Fiber Patch: Cut a carbon fiber fabric patch slightly larger than the damaged area. Ensure that the fibers are aligned in the same direction as the original panel.

- Mix Epoxy Resin: Mix epoxy resin according to the manufacturer’s instructions.

- Apply Epoxy to Patch: Apply a thin layer of epoxy resin to the carbon fiber patch, ensuring that the fibers are thoroughly wetted out.

- Apply Patch to Panel: Place the carbon fiber patch over the damaged area, aligning the fibers with the original panel.

- Apply Release Film and Peel Ply: Cover the patch with release film and peel ply to prevent the epoxy from sticking to the vacuum bagging materials.

- Apply Vacuum Bagging (Optional): Apply vacuum bagging materials over the patch to compress the repair and remove excess resin.

- Cure the Epoxy: Cure the epoxy according to the manufacturer’s instructions. Use a heat gun or oven to accelerate the curing process if necessary.

- Remove Vacuum Bagging Materials: Once the epoxy is cured, remove the vacuum bagging materials, release film, and peel ply.

- Sand the Repair: Sand the repaired area with progressively finer grits of sandpaper to blend it seamlessly with the surrounding surface.

- Apply Clear Coat or Paint: Apply a clear coat or paint to the repaired area to match the panel’s original finish.

- Polish the Surface: After the clear coat or paint has dried, polish the surface with a polishing compound to restore its gloss and luster.

Post-Repair Inspection

After completing the repair, thoroughly inspect the panel to ensure that the damage has been adequately addressed and that the repair meets the required standards. Check for any signs of cracks, delamination, or other defects.

Use non-destructive testing (NDT) methods, such as ultrasonic testing or thermography, to evaluate the integrity of the repair. These methods can detect hidden flaws or imperfections that may not be visible to the naked eye.

Conclusion

Repairing carbon fiber panels requires specialized knowledge, skills, and materials. By following the techniques outlined in this article and taking necessary safety precautions, you can effectively repair carbon fiber panels and restore their strength, stiffness, and appearance. Remember to assess the damage thoroughly, choose the appropriate repair method, and inspect the repair carefully to ensure its integrity.

Semoga artikel ini bermanfaat.