How to Repair Old Wiring Harnesses

Old wiring harnesses can be a challenge to deal with, but they don’t have to be. With the right tools and a bit of know-how, you can repair them and keep your classic car or other vehicle running smoothly. In this article, we’ll take a look at how to repair old wiring harnesses.

Why Repair Old Wiring Harnesses?

There are a few reasons why you might want to repair old wiring harnesses. First, they can be expensive to replace. A new wiring harness can cost hundreds or even thousands of dollars, depending on the vehicle. Second, old wiring harnesses can be difficult to find. If you have a classic car or other vehicle, it may be difficult to find a replacement wiring harness that is compatible. Finally, old wiring harnesses can be just as good as new if they are repaired properly.

Tools and Materials

Before you start repairing your old wiring harness, you will need to gather the following tools and materials:

- Wire stripper

- Crimper

- Soldering iron

- Solder

- Heat shrink tubing

- Electrical tape

- Multimeter

- Wiring diagram

Steps to Repairing Old Wiring Harnesses

Once you have gathered the necessary tools and materials, you can begin repairing your old wiring harness. Here are the steps involved:

1. Disconnect the Battery

Before you start working on the wiring harness, it is important to disconnect the battery. This will prevent any accidental shocks or electrical damage.

2. Inspect the Wiring Harness

The first step is to inspect the wiring harness for any damage. Look for things like cracked or broken wires, loose connections, and corrosion. If you find any damage, you will need to repair it before you can continue.

3. Clean the Wiring Harness

Once you have inspected the wiring harness, you will need to clean it. This will remove any dirt, grease, or corrosion that may be present. You can use a mild detergent and water to clean the wiring harness. Be sure to dry the wiring harness thoroughly before you continue.

4. Repair Any Damaged Wires

If you find any damaged wires, you will need to repair them. The best way to repair damaged wires is to solder them together. However, you can also use crimp connectors.

5. Solder the Wires Together

If you are soldering the wires together, you will need to strip the insulation from the ends of the wires. Then, twist the wires together and apply solder to the joint. Be sure to use a good quality solder and a hot soldering iron.

6. Use Crimp Connectors

If you are using crimp connectors, you will need to strip the insulation from the ends of the wires. Then, insert the wires into the crimp connector and crimp the connector closed. Be sure to use the correct size crimp connector for the wires you are using.

7. Insulate the Connections

Once you have repaired the wires, you will need to insulate the connections. This will protect the connections from moisture and corrosion. You can use heat shrink tubing or electrical tape to insulate the connections.

8. Use Heat Shrink Tubing

If you are using heat shrink tubing, you will need to slide the tubing over the connection. Then, use a heat gun to shrink the tubing. Be sure to use the correct size heat shrink tubing for the connection you are insulating.

9. Use Electrical Tape

If you are using electrical tape, you will need to wrap the tape around the connection. Be sure to overlap the tape as you wrap it. This will ensure that the connection is properly insulated.

10. Test the Wiring Harness

Once you have repaired and insulated the connections, you will need to test the wiring harness. This will ensure that the wiring harness is working properly. You can use a multimeter to test the wiring harness.

11. Use a Multimeter

To test the wiring harness, you will need to connect the multimeter to the positive and negative terminals of the battery. Then, use the multimeter to check the voltage at each of the connections in the wiring harness. If the voltage is correct, the wiring harness is working properly.

12. Reconnect the Battery

Once you have tested the wiring harness, you can reconnect the battery. Be sure to connect the positive terminal first, followed by the negative terminal.

Tips for Repairing Old Wiring Harnesses

Here are a few tips for repairing old wiring harnesses:

- Take your time. Repairing old wiring harnesses can be time-consuming, so don’t rush the process.

- Be careful. Wiring harnesses can be delicate, so be careful not to damage them.

- Use the right tools. Using the right tools will make the job easier and safer.

- Follow the instructions. Be sure to follow the instructions carefully when repairing your old wiring harness.

- If you are not comfortable repairing your old wiring harness, take it to a professional.

Specific Issues and How to Address Them

- Brittle or Cracked Insulation: This is a common problem in old wiring. The insulation can become brittle and crack over time due to heat, age, and exposure to the elements. To fix this, carefully remove the old insulation with a wire stripper or utility knife, being careful not to damage the wire itself. Then, replace the insulation with heat shrink tubing or electrical tape. Heat shrink tubing is generally preferred as it provides a more durable and professional-looking repair.

- Corroded Terminals: Corrosion can build up on terminals over time, causing poor electrical connections. To clean corroded terminals, use a wire brush or sandpaper to remove the corrosion. You can also use a terminal cleaner spray. Once the terminals are clean, apply a dielectric grease to prevent future corrosion.

- Broken Wires: Broken wires can be caused by a variety of factors, such as vibration, stress, or physical damage. To repair a broken wire, strip the insulation from the ends of the wire and solder them together. You can also use crimp connectors to join the wires. Be sure to insulate the connection with heat shrink tubing or electrical tape.

- Loose Connections: Loose connections can be caused by vibration or corrosion. To tighten loose connections, use a pair of pliers to crimp the connector tighter. You can also use a terminal cleaner spray to clean the connections and improve conductivity.

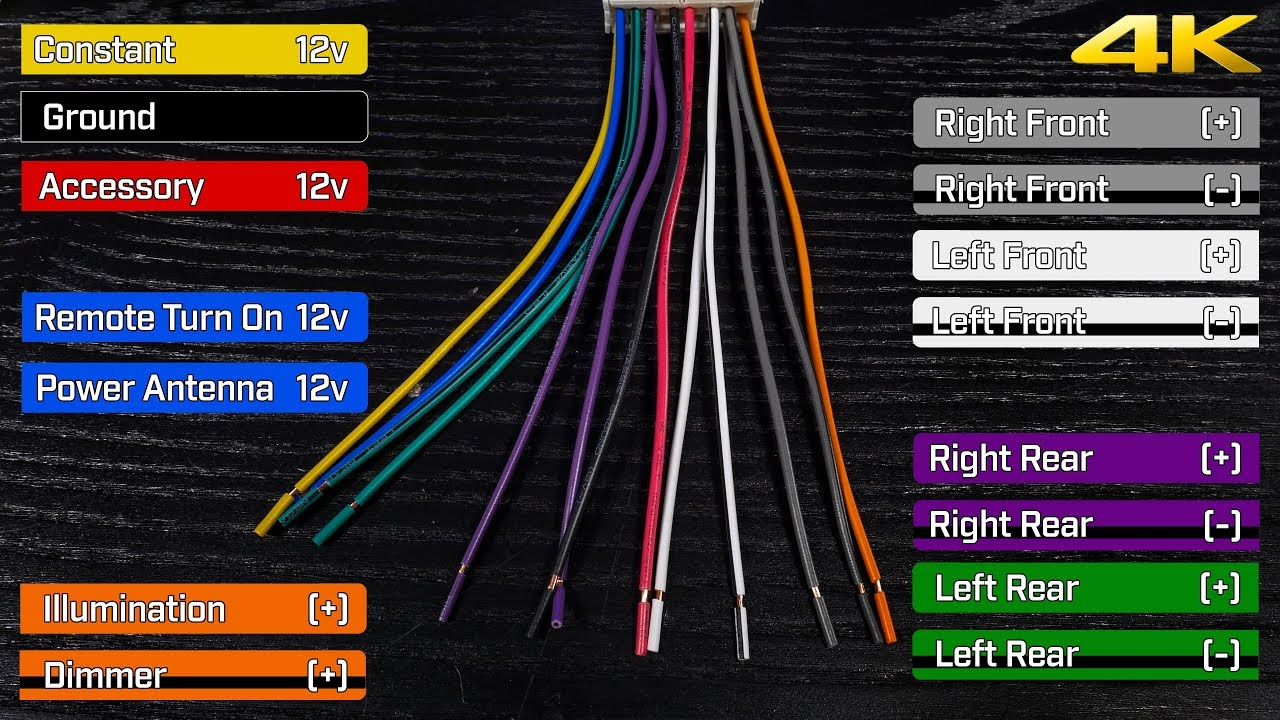

- Identifying Wires: Old wiring harnesses can be difficult to identify, especially if the original markings have faded or been removed. A wiring diagram is essential for identifying the wires and ensuring that they are connected correctly. If you don’t have a wiring diagram, you can try to trace the wires back to their source. You can also use a multimeter to test the wires and determine their function.

Safety Precautions

When working with electrical wiring, it is important to take safety precautions to protect yourself from electric shock. Here are a few safety precautions to keep in mind:

- Disconnect the battery before working on the wiring harness.

- Wear rubber gloves to protect yourself from electric shock.

- Work in a well-lit area.

- Avoid working in wet conditions.

- If you are not comfortable working with electrical wiring, take the wiring harness to a professional.

Conclusion

Repairing old wiring harnesses can be a challenging but rewarding task. By following the steps outlined in this article, you can repair your old wiring harness and keep your classic car or other vehicle running smoothly. Remember to take your time, be careful, and use the right tools. With a little patience and effort, you can save money and keep your vehicle on the road for many years to come.

Good luck!